Smith-Emery Laboratory Tests

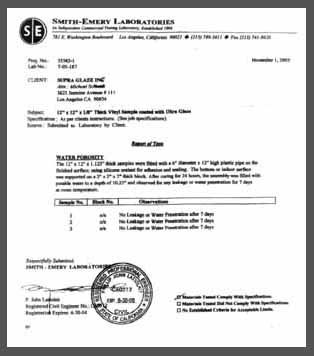

Ultra-Glaze Test One: Water Porosity

The 12''x12''x1.25'' thick samples were fitted with a with a 6'' diameter x 12'' high plastic pipe on the finished surface; using silicaone sealant for adhesion and sealing. The bottom or indoor surface was supported on a 2'' x 2'' x 2'' thick block. After curing for 24 hours, the assembly was filled with potable water to a depth of 10.25'' and observed for any leakage or water penetration for 7 days at room temperature.

Sample No. |

Block No. |

Observations |

| 1 | n/a | No Leakage or Water Penetration after 7 days |

| 2 | n/a | No Leakage or Water Penetration after 7 days |

| 3 | n/a | No Leakage or Water Penetration after 7 days |

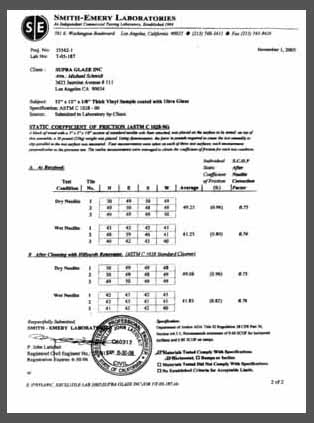

Ultra-Glaze Test Two: Static Coefficient of Friction (ASTM C 1028-96)

A block of wood with a 3'' x 3'' x 1/8'' section of standard neolite sole liner attached, was placed on the surface to be tested; on top of this assembly a 50 pound (22kg) weight was placed. Using dynamometer, the force in pounds required to cause the test assembly to slip parallel to the test surface was measured. Four measurements were taken on each of three test surfaces, each measurement perpendicular to the previous one. The twelve measurements were averaged to obtain the coefficient of friction for each test condition.

A. As Received:

| TEST CONDITION | TILE NO. | N | E | S | W | AVERAGE | (fc) | S.C.O.F |

| DRY NEOLITE | 1 | 50 | 49 | 50 | 49 | |||

| 2 | 49 | 50 | 48 | 49 | 49.25 | (0.96) | 0.75 | |

| 3 | 49 | 49 | 49 | 50 | ||||

| WET NEOLITE | 1 | 43 | 42 | 42 | 43 | |||

| 2 | 40 | 39 | 40 | 41 | 41.25 | (0.80) | 0.74 | |

| 3 | 40 | 42 | 43 | 40 |

B. After Cleaning with Hillyurds Renovator. (ASTM C 1028 Standard Cleaner)

| DRY NEOLITE | 1 | 50 | 49 | 49 | 48 | |||

| 2 | 50 | 49 | 48 | 49 | 49.08 | (0.96) | 0.75 | |

| 3 | 49 | 50 | 49 | 49 | ||||

| WET NEOLITE | 1 | 42 | 43 | 42 | 43 | |||

| 2 | 42 | 43 | 41 | 41 | 41.83 | (0.82) | 0.76 | |

| 3 | 41 | 42 | 42 | 40 |

PRODUCTS: